Laser Cutting: A History of Innovation

Our clients are always looking for top notch results. In many cases, laser cutting is the ideal manufacturing process. Laser cutting provides an efficient method for creating complex shapes, higher sheet utilization and gives us a great deal of capability.

We are always looking to innovate through the use of leading technology. Our approach to laser cutting is no exception. Through a combination of premium equipment, and refined quality processes, we provide our customers with excellent results.

Laser cutting technology has a unique history that is marked by innovation and continual improvement, two staples in Dane Manufacturing’s culture. Let’s take a quick look.

History of Laser Cutting

The first concept of laser cutting was originally conceived in 1917 by Albert Einstein who created the original scientific concept behind the modern laser. What proceeded was a rapid period of innovation and growth that would shape the use of laser cutting in manufacturing.

1960: The first ever working laser is created by Theodore Maiman. His design using a synthetic ruby laser was met with skepticism.

1964: Scientists at Bell Labs saw potentional in Maiman’s invention and set out to improve on it. They developed thermal cutting techniques by inventing a gas laser using CO2 mixture.

1965: Western Engineering Research Center becomes the first to apply the concept of laser cutting to manufacturing.

1969: Boeing company becomes the first commercial user of gas laser cutting equipment, who applied the technology to its production lines in an effort to create a more efficient manufacturing process.

1979: Prima Industrie out of Italy invented 3D laser cutting technique that expanded its capabilities and potential uses in manufacturing.

1980s: After 20 years of development, the first commercial fiber lasers hit the market, further expanding the capabilities and applications suitable for laser cutting.

Laser Cutting Technology at Dane Manufacturing

Here at Dane Manufacturing, we prioritize innovation and strive to continually provide our customers with the best metal solutions around. Doing that requires us to regularly invest in premium caliber equipment, and to train our teams to use them effectively and efficiently. Our laser cutting equipment is no exception.

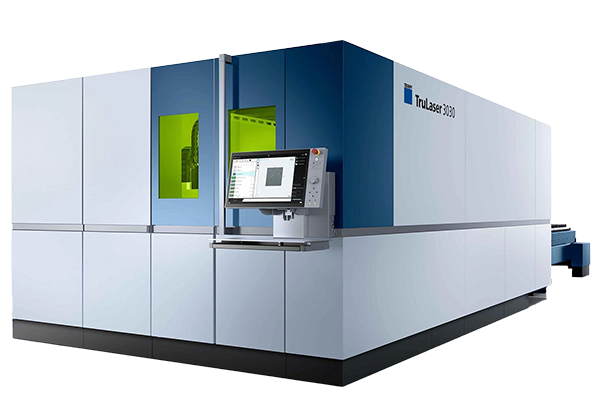

Our partner, Trumpf, is one of the world leaders in laser cutting technology. We run multiple Trumpf 3030 machines with reliable TruFlow lasers that produce extremely high cut quality. The Trumpf programming software that guides our lasers to cut to exceptionally tight tolerances and parameters, is second to none. Combined with our automated STOPA storage system that allows us to run automated production schedules 24 hours a day, we have the perfect laser process for the production of your laser-cut parts.